.png)

Simplicity for your reality

Ask for your 7 days licence

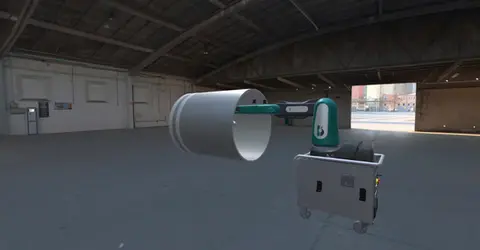

A standalone application for interacting and visualizing your Virtual Reality scenarios.

WHAT CAN YOU DO WITH XR TWIN ?

Review CAD and point cloud in virtual reality. Visualize your digital twin at 1:1 scale using virtual reality. Navigate, measure and spot design issues earlier.

IMPORT

Share your simulation and deploy your executable. Train your users on complex tasks.

REPORT & ANALYZE

Manipulate, touch, and try your product before building it. Experiment and validate product usage.

SIMULATE

Reproduce the physical behavior of your processes interactively. Ensure parts fitting, cables routing, and tool accessibility.

CONFIGURE

PLANS

What is a digital twin and how does XR Twin help with this?

A digital twin is a virtual replica of a physical process or product. XR Twin allows the creation and simulation of industrial environments in 3D, facilitating problem anticipation and process optimization.

Why choose XR Twin for a virtual reality industry?

XR Twin offers 1:1 scale VR immersion with realistic interactions. Ideal for evaluating design, production feasibility and ergonomics in a precise virtual environment.

What types of files can be used with XR Twin for industrial simulations?

XR Twin supports formats such as CAD models and point cloud files. This makes it easy to create custom simulations from your own 3D data.

XR Twin is an industrial simulation creation software accessible to everyone.

In addition to being "no code", the application is easy to use to configure your digital twin from your data. With this digital twin, edit, visualize, interact with and analyze your simulation endlessly, even during your process, design or product review.

The goal? Anticipate problems. Because in simulation, mistakes don't cost anything. On the contrary, make them.

With XR Twin, we can do in 24 hours what used to take a month to set up. It's extremely fast .

We have gone from a test phase with cardboard mock-ups to a more realistic and representative virtual reality test phase.

Mathieu LAUER | SEW USOCOME France